The Story of Henry J. Kaiser

Henry John Kaiser, (May 9, 1882 – August 24, 1967) was an American industrialist who became known as the father of modern American shipbuilding.

His many accomplishments include:

Hoover Dam and Grand Coulee Dam

From its founding in 1914, Kaiser established itself as a road building company, but as money dried up for road building at the beginning of the Depression, Henry Kaiser looked to dam building, which was one of the main types of large Depression-era public works projects. Kaiser led the six-company consortium that built what was then the largest dam in the world, the Hoover Dam. The Company was involved in many of the dam construction projects that helped modernize the American West by providing power and irrigation, including the Bonneville Dam and Grand Coulee Dam. Grand Coulee, which followed the Hoover Dam, replaced the Great Pyramids as the world’s largest manmade structure when it was completed. Henry Kaiser established his reputation as a team builder with these projects by working with the other companies that joined Kaiser in joint ventures, as well as with the unions, to expand the limits of what builders could accomplish.

Kaiser Liberty Ships

During World War II, Kaiser became one of the most famous industrial companies in the United States for its contributions to the war efforts. Kaiser built huge numbers of ships in record times, including “baby flat top” aircraft carriers. Kaiser had the equivalent of 20 military divisions, 300,000 workers, engaged in manufacturing munitions, planes, and ships. Kaiser’s shipyards in Oregon and California competed to out-produce each other, and the shipyard in Richmond, California launched the SS Robert E. Peary after only four days, 15 hours and 26 minutes after laying the first strip of steel that became the keel. By the end of WWII, Kaiser’s shipyards had built 1,383 merchant ships and 107 warships.

Production Plants for the Kaiser Industries Companies in the 1940’s and early 1950s

Kaiser built a number of plants for the basic industrial companies it owned, including facilities for Kaiser Aluminum (Chalmette, LA); Kaiser Cement (Permanente, CA); and Kaiser Steel (Fontana, CA). For the Fontana mill, Kaiser built the infrastructure needed to mine and transport iron ore from the Eagle Mountain iron ore mine to Fontana, including a 52-mile railroad line to connect the remote Eagle Mountain location to the existing rail line.

Snowy Mountains Hydroelectric Power Project

In the 1950s, Kaiser led the six-company consortium that built the Snowy Mountains project, which provided irrigation and electricity to southeastern Australia. The 25-year, on-time and under-budget project included the construction of 16 dams, seven hydroelectric stations, over 85 miles of tunnels, 50 miles of aqueducts, which included a 14-mile canal cut through the granite heart of the Snowy Mountains.

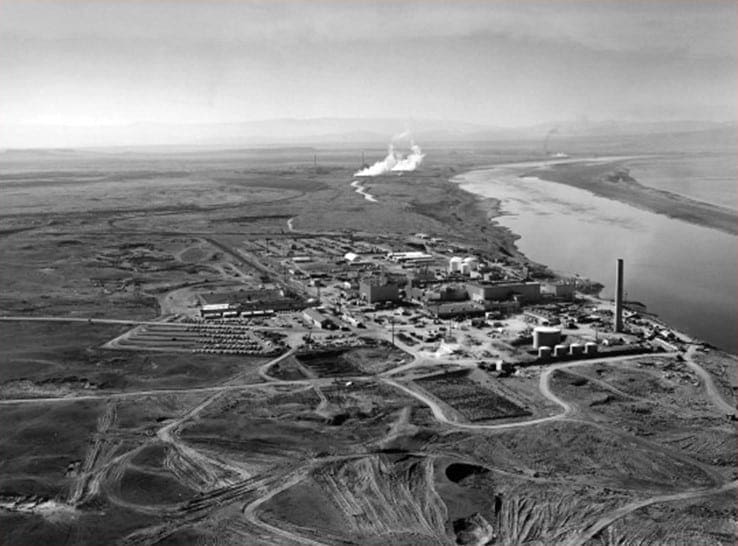

Hanford Nuclear Reservation

For more than 14 years, Kaiser was responsible for facilities management, design and construction upgrades, and construction management for all nuclear and non-nuclear facilities and infrastructure on the 570-square-mile Hanford nuclear site. Under four successive contracts worth $1.3 billion, Kaiser consistently achieved more than 90% award fee, reduced infrastructure and landlord costs by $52 million, achieved $120 million in savings on 30 projects over a two-year period through value engineering initiatives, and reduced utilities costs more than 50%,a $10 million savings. At the contract’s peak, Kaiser managed 800 professionals and 1,200 craft labor on 1,600 assignments.

I-595 Port Everglades Expressway

Kaiser provided design and construction management services and right-of-way acquisition on this $1.2 billion project that was completed ahead of schedule and $80 million under budget. The project included 20 separate construction packages, 310 lanes miles of highway, 93 bridges, three four-level interchanges,14 two- or three-level interchanges, relocation of three railroads, and two water crossings. The project also required a six-year maintenance-of-traffic plan to keep 150,000 vehicles per day flowing on 1-95 at the 1-595 intersection.

Boston Harbor

Kaiser was the program and construction manager for the $3.5 billion, 14-year cleanup of the Boston Harbor. The Boston Harbor Project was the largest capital improvement project in New England and the second largest wastewater treatment plant in the country. The main feature of the project was the construction of a 1.1 billion gallons per day wastewater treatment facility and a nine-mile ocean outfall tunnel. When completed in 2002, the facility provided secondary wastewater treatment for 2.5 million people in 43 cities and towns in eastern Massachusetts. At the project’s peak, Kaiser managed the activities of 90 prime contractors and more than 3,200 personnel. Through to completion, Kaiser saved $600 million in project costs and accelerated the court-mandated schedule by two years. More than 28 million hours had been worked with a lost-time accident rate of 4.0, which is 35 percent below the national average for heavy construction.

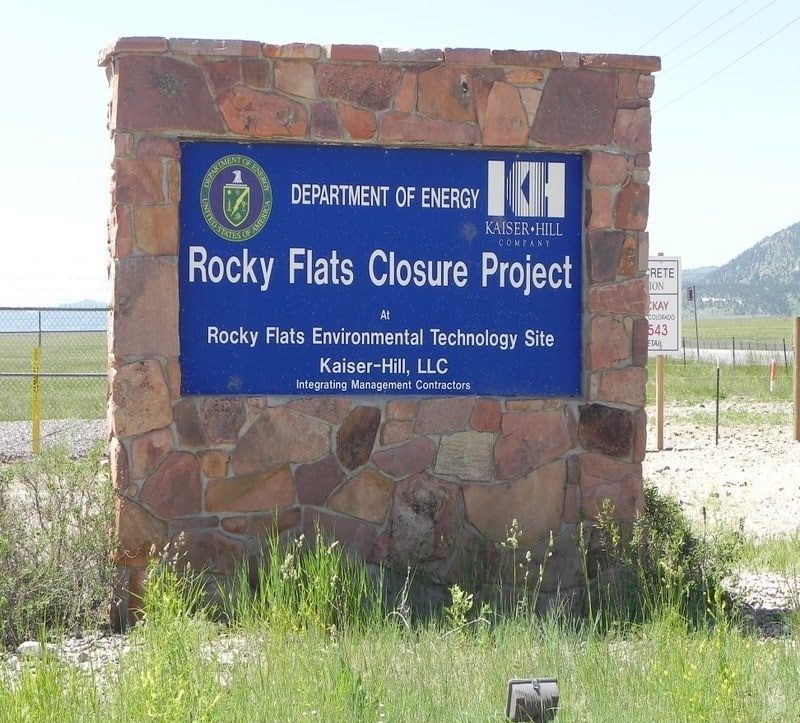

Rocky Flats

Valued at $3.5 billion over a five-year period, Kaiser Engineers’ was a 50-50 joint venture partner with CH2M Hill to manage the cleanup of the Department of Energy’s (DOE’s) Rocky Flats site in Colorado. The site was comprised of 384 acres of nuclear and industrial complex facilities, consisting of 650,000 square feet of warehouse and office space, 130,000 square feet of laboratories, 1,400,000 square feet of industrial facilities, and 1,100,000 square feet of nuclear production facilities. Underpinning the success of the Rocky Flats commercial arrangement was the use of a strong employee incentive structure that enabled the sharing of 20% of the fee earned on the program with employees. Kaiser-Hill negotiated with local labor unions to ensure that incentivization was passed on to hourly workforce in addition to management and non-bargaining personnel. Since contract award, more than 50 years and nearly $30 billion were shaved off DOE’s original clean up schedule. The project was completed in 2005 and buildings once referred to as ‘the most dangerous in America’ by ABC News Nightline were converted into a 5,237 national wildlife refuge with pollution levels 13 times lower than the DOE standard.

Nova Hut

Kaiser led the engineering and construction efforts to build a $262-million steel mill in Ostrava, the Czech Republic. The project began in 1993, when Kaiser produced a feasibility study financed by the U.S. Trade and Development Agency. The new mill helped modernize the Czech Republic’s metals industry and made the country more competitive in the modern, global marketplace. The mini-mill consists of a ladle metallurgy facility, medium slab caster (with twin slab capability), equalizing/reheat furnace, and a two-stand reversing hot strip mill.